![Generator Parts - Diesel Generators & Electric Generators [With Features & Pictures] Generator Parts - Diesel Generators & Electric Generators [With Features & Pictures]](https://engineersreferencebookspdf.com/wp-content/uploads/2023/11/3.jpg)

Generator Parts – Diesel Generators & Electric Generators [With Features & Pictures]

What is a Generator?

Generators are devices that supply power when no power is available from the adjacent array. It is mainly used to provide backup power to offices, organizations, or homes in the event of power outages or blackouts, but it can also be used as an important source of power in places such as mines where nearby power grids are accessible or difficult to access. . . . Agriculture, including new developments and construction. In this way, knowing all the characteristics of the machine you can BE We are more prepared if the machine breaks down during use.

Here are some important things to consider before buying a machine.

Pollution: Diesel-powered generators produce large amounts of emissions or emissions of air pollutants such as carbon monoxide and nitrogen oxides.

High installation costs: Although fuel costs are low, the cost of installing the engine is high because it requires knowledge and understanding of all the parts.

Regular maintenance: To ensure the longevity of your machine, it should be inspected regularly. It is important to change the oil, replace the channels, and periodically check other moving parts.

Bulky: heavy and difficult to carry from one place to another.

Parts of Generator

Let’s take a closer look at the output phase. –

1. Engine

Every machine has an engine or motor that converts the fuel source into electricity that can move or do mechanical work. Therefore, the motor is sometimes called the main power source of the motor. In an engine, the engine uses a fuel source (gas, oil, diesel, propane, biodiesel, water, compressed air, or hydrogen) to generate mechanical energy and convert it into electricity by the generator as electricity or electricity.

All diesel engine designs are designed to provide maximum power flow using a specific fuel or other power source. Some commonly used engines in mechanical design are reciprocating engines, steam engines, turbine engines, and mechanical engines.

2. Oil system

A fuel pump operates a system that stores the correct amount of fuel and pumps it to the engine. The tank stores enough fuel to power the engine for the same amount of time. The fuel pipe connects the tank to the engine and the return pipe connects the engine to the fuel tank for fuel recovery. The fuel pump moves fuel from the tank through the fuel lines to the engine. The oil channels filter out the remaining fuel before it is delivered to the engine. fuel injector

The fuel is atomized and injected directly into the combustion chamber of the engine.

3. Voltage transmitter

A voltage regulator directly controls the output voltage. There is a lot to cover in this article alone, so another section is needed to explain the entire voltage control process. Simply put, it ensures that the power comes out at a constant voltage. Otherwise, you will see a significant difference in the running speed or operating speed of your machine.

All the electrical equipment we use cannot support the supply of electricity. In this context, this unit does an amazing job of keeping everything smooth and consistent.

A)Electric Generator

A generator is a machine used to provide electrical power and can be used in a variety of applications, from small household appliances to large modern machines. A popular option is the use of the energy matrix produced from petroleum products, wind turbines, or steam engines in power plants.

There are many different types of engines, including gasoline engines, small engines, rotary engines, domestic engines that can run on flammable gases, standby engines that maintain power during a fire, and the largest industrial producers. This article provides the most important information about machine tools, work instructions, and main parts, which are called manufacturers.

Parts of the Electric Generator

1. Engine

The mechanical part or area is the heart of the manufacturer. The engine of the engine is used by natural gas or oil. The engine runs on oil, and when the engine is running, many components, including generators and battery components, convert engine energy into electrical energy needed for various devices.

In a generator, an engine uses a fuel source (eg, oil, gasoline, propane, natural gas, biomass, compressed air, water, or hydrogen) to convert the engine’s energy in the housing into electricity. All engine engine designs hope to use a specific fuel or other energy source to create the most efficient flow of energy. Some engines commonly used in production applications are turbine engines, steam engines,

Alternative engines and microturbines.

2. Oil system

It is a framework for an engine that works with fuel in mind to save and deliver fuel to the engine efficiently. The fuel system is an important part of the generator. Without fuel, the engine will not run. This means that the correct fuel must be fed into the frame, and the generators must have fuel and space if the work of the frame is to continue.

The tank stores enough fuel to operate the frame for the same period. The fuel pipe connects the tank to the main engine and the pipe connects the engine to the fuel source for fuel return. The fuel pump delivers fuel to the engine from a source in the oil pipes. The channel area filters waste from the fuel before it is used by the engine. Fuel injectors crush or soften the fuel and send it directly into the combustion chamber.

framework

3. Producer and end of production

The converter is one of the most important parts of the engine that converts the mechanical power produced by the engine to produce electricity. The generator is called the “genhead,” the part of the engine that produces electricity from the mechanical power provided by the engine.A converter consists of a rotor (or frame) and a stator. The rotor moves around the stator to create a rotating electrical output. A rotor works with moving parts that produce a rotating magnetic effect through 1) permanent magnets, 2) applied excitation, and 3) induction. The rotor creates a moving magnetic environment around the stator that contains a voltage difference between the windings. A current version comes from the manufacturer.

4. Cooling, exhaust, and lubrication systems

Special guidelines are required for the temperature of mechanical parts to prevent overheating during operation. Electricians can use cooling, touch, or both to control the temperature of the frame they are working on. As fuel is consumed in the combustion chamber, the converter also produces exhaust gases. Tubular shells eliminate hazardous gases released from the shell during operation. There are many moving parts in generators, each of which must be lubricated.

Ensures smooth operation. The lubrication system frame ensures that all output components are well-lubricated.

5. Control panel

The control panel or manufacturer’s board will vary depending on the UI. This allows the framework administrator to control the various output parameters and change them as needed. These primary controls include the voltage value, base current, and output frequency set by the manufacturer. System control is supported by a series of displays and gauges, and the manufacturer’s configuration is created by advancing switches and buttons.

6. Battery charger

As with other machines, the manufacturer began to use batteries. Since this battery must be charged, the frame also includes a battery charger to recharge the battery while the frame is running.

7. Voltage transmitter

The generator converter now produces the main output. This is not a good time to skimp on battery storage units or engine management. All things considered; Direct current is required. A voltage regulator determines the current-voltage and converts it from alternating current to direct current.

8. Main frame/jump

The slide or main frame is the seat of the mechanical parts that hold all the parts and components. Skids are made so the builder can sit on a large floor pad or attach to a trailer for easy frame transport. This can also ensure that machine parts are properly positioned, which is important for efficient and safe operation.

9. lubrication system

Since generators contain some moving parts, they need a lubrication point. The lubricating part prevents the sliding part from developing excessive friction and heat, which starves the frame.

B) Diesel generators

Diesel generators produce non-stop or standby power for various users such as homes, schools, emergency clinics, and industrial facilities. It can be large enough to easily transport or large enough to fit in your home. However, it is a suitable option for each user. Diesel generators convert fuel energy into electrical energy to power loads.

What do people look for before buying a diesel engine?

Simple: – Diesel generators can run for a long time. With proper support and maintenance, it can still be used even in harsh environments.

Low maintenance:- Compared to gas engines, diesel engines are easier to maintain. Because there are few external parts, maintenance is not difficult.

AIR: – Diesel is flammable. However, diesel fuel is much less prone to ignition than other fuels such as gasoline.

Accessibility: – Easy approval of diesel fuel makes engine manufacturers more important. Diesel is more convenient and practical because it is cheaper.

Efficiency: – Diesel generators are more environmentally friendly compared to other engines. So it runs faster than other petrol engines.

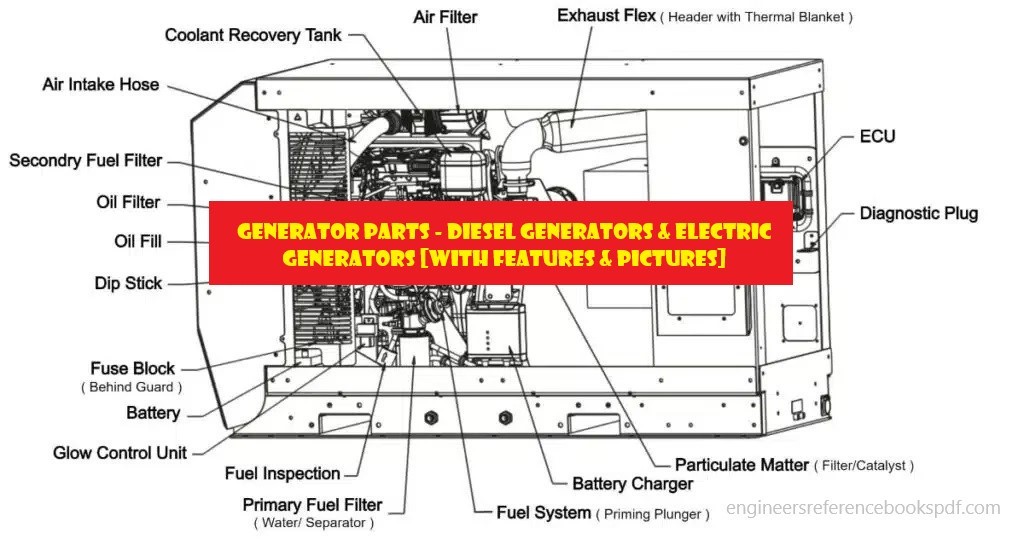

diesel engine parts

1. converter

A converter is a component that generates electricity. Here electromagnetic induction works as follows: There are many complex parts in the converter, but one of the main parts or components is the rotor. It consists of a rotating shaft with the mechanical power provided by the machine and several permanent magnets placed around it, creating a magnetic field.

2. fuel system

Most fuel systems, or frames, consist of a fuel tank and pipes connected to the engine. Ultimately, the size of the fuel tank determines how long your engine will run. A silent exhaust system comes standard with a fuel tank located under the engine.

3. Voltage transmitter

The regulator or voltage regulator is the most complicated part of the generator. There is a good reason to control the voltage output here. Basically, this ensures that the generator produces a regulated and consistent voltage. Without a voltage regulator, there will be large variations in motor speed. All types of electrical equipment that we use cannot support an uninterrupted power source. As a result,

The purpose of using this feature is to keep everything smooth and consistent.

4. Heating and exhaust system

These two sections are very functional. The function of the cooling system is to prevent overheating of the power supply. Coolant is supplied from the engine to ensure adequate heat for all engines and engines. Because the heater takes all this heat through a heat exchanger and sends it out of the generator. The tube framework is the same way as the tube system of a car. This captures all the gas produced by the diesel engine and feeds it into:

Remove the tube frame and remove it from the electrical assembly.

5. Lubrication system

The lubrication system is the part that connects to the engine and pumps oil to keep each part flowing without affecting other parts. Without a proper lubrication system, your engine will break down.

6. Battery charger

Diesel engines need an electric motor to help them run. The small car runs on a battery that needs to be recharged.

7. Control panel

This part is only for managing and controlling the machine. All controls, including the start button, frequency switch, engine fuel gauge, coolant temperature gauge, etc., allow the user to perform various functions or check special characters.

The control panel implements monitoring, maintenance, and control by starting and stopping the engine and monitoring the engine and engine.

The control panel will do everything right. Synchronous tasks can also be assigned to enable parallel operations.

8. main meeting framework

Each manufacturer must be confirmed, and this is the main framework of the event. In this building, there is a complete machine and all kinds of machine tools are made there.

The design can be open, leave everything as it is, or closed (relief) for more navigation and noise. Open generators are usually stored in a weatherproof layer to prevent damage.

Conclusion

You’ll be fine, and you’ll know how electrical and electronic machines work. Simply put, the motor will send the power from the converter and everything will change to the internal flow of electricity and you will see the beautiful places and the power input.