Fuel injection system: diagram, parts, operation, types

What is a fuel injection system?

A fuel injection system is a type of internal combustion engine system that uses fuel injectors to provide precise and controlled delivery of fuel to the combustion chamber or engine cylinders. This ensures efficient combustion by atomizing the fuel and injecting the fuel under high pressure at the right time into the engine cylinders.

Carburetors were widely used on engines before fuel injectors were invented and this engine is still in use today. In fact, many other machines still use carburetors, including lawnmowers and chainsaws. Due to the complexity of controlling all the requirements of an automobile, the fuel injection system was offered as a better alternative.

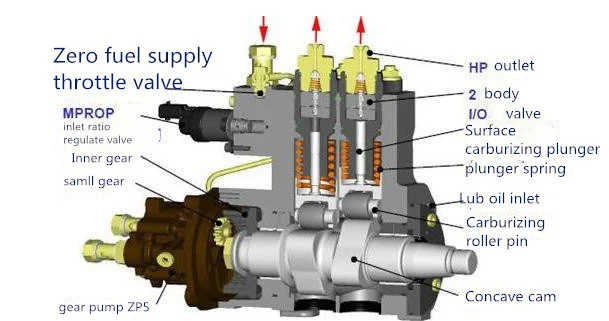

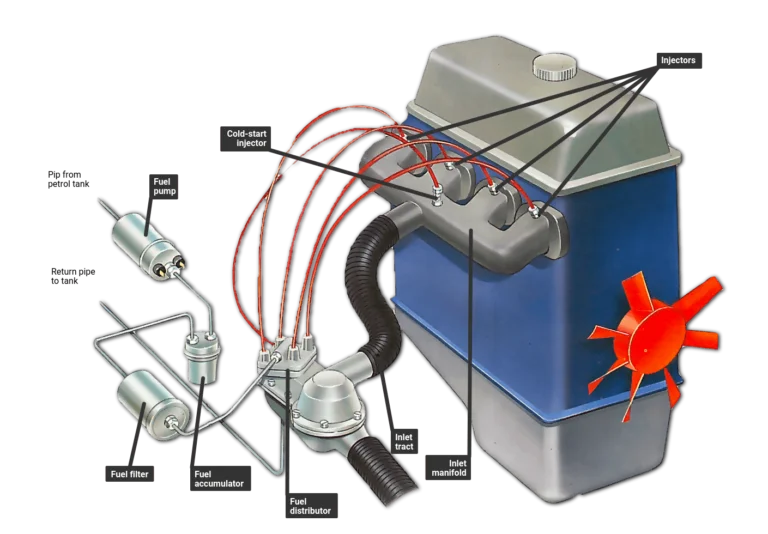

Fuel injection system diagram

Fuel injection systems come in many different types, but they all share some basic components. These components include the fuel pump, fuel injectors, fuel pressure regulator, and the electronic control unit (ECU) that manages the system’s operation.

Vehicles today use fuel injection systems to increase fuel efficiency, reduce emissions and increase performance. To comply with pollution standards and improve engine performance, they also allow for better control of the air/fuel mixture.

Fuel injection system components

The fuel injection system is a complex system with many important components. The essential parts of the fuel injection system are:

Fuel tank

Fuel pump

Injection pump

Fuel filter

Regulator

Fuel pressure regulator

Fuel Injector

Butterfly body ga

Modular Engine Control Unit (ECM)

Fuel Tank # 1

The fuel tank acts as a reservoir for supplying fuel, helping to maintain temperatures below the flash point. In addition, the fuel tank plays an important role in dissipating heat from the fuel back to the engine.

#2 Fuel pump

Fuel-pumped fuel transfers from the fuel tank to the fuel injectors. Electric or mechanical fuel pumps are available. The purpose of the fuel pump is to maintain a constant fuel pressure.

#3 Injection Pump

The mechanism that injects fuel into the cylinders of a diesel engine is called the injection pump. A toothed belt (usually a timing belt) that also drives the camshaft is used to drive the injection pump indirectly from the crankshaft.

#4 Fuel filter

The fuel filter reduces the amount of dirt, debris and other contaminants reaching the fuel injectors and helps prevent fuel contamination. A clogged fuel filter can reduce engine performance and even damage the fuel injection system.

Fuel injection system diagram

#5 Governor

Speed governor The function of the governor is to regulate fuel to the engine cylinder to control the speed of the component, keeping the speed constant at all times. operating conditions. engine.

6 # Fuel Pressure Regulator

The function of the fuel pressure regulator is to control the fuel pressure and ensure a constant flow of fuel into the engine. This ensures that the fuel pressure remains within a predetermined range.

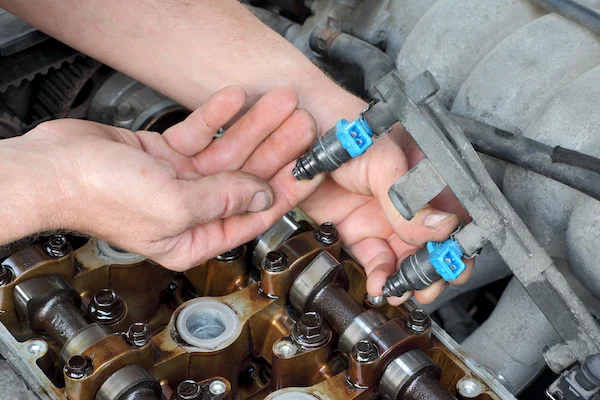

#7 Fuel Injector

The part that puts fuel into the combustion chamber of an engine is called the fuel injector. Fuel is injected into the engine through the fuel injectors at high pressure and in a precise pattern.

#8 Throttle body

The throttle body is an engine part that controls how much air is allowed into the engine. Usually, it is located between the air filter and the intake manifold.

#9 The Engine Control Module (ECM) The

ECM of the fuel injection system is called its brain. Fuel and air mixtures, fuel injection timing, and other parameters are adjusted by the ECM using input from various sensors to improve engine performance and fuel economy.

Also read: Understanding how the distributor less ignition system works

Fuel injection system function

The engine’s fuel injection system ensures efficient combustion and optimal performance by delivering fuel precisely and in a controlled manner according to engine operating conditions. As a rule, it consists of an electronic control unit, a fuel pressure regulator, a fuel injector, and a fuel pump (ECU).

The fuel pump pressurizes the fuel and delivers it to the fuel injectors. The injector delivers fuel to the engine’s combustion chamber. The fuel pressure regulator maintains fuel pressure within a specific range, while the ECU analyzes engine load, rpm, and temperature to determine the best fuel delivery.

Fuel injection system diagram

By adjusting the amount of fuel, timing, and type of injection, the fuel injection system regulates the distribution of fuel. As a result, the air-fuel mixture can be precisely controlled, ensuring efficient combustion and producing the best engine performance, fuel economy, and emissions reduction.

The type of system used affects the specific function of the fuel injection system. For example, a port fuel injection system delivers fuel to the intake port, while a direct injection system delivers fuel directly into the combustion chamber. Its overall purpose is to accurately and efficiently fuel the engine to optimize performance and performance.

Types of Fuel Injection Systems

Fuel injection systems come in several different types, each with its own unique qualities and benefits. Here are some more typical fuel injection system designs:

Single point injection or throttle body (TBI)

Multipoint fuel injection (MPI)

Direct injection (DI)

Internal fuel injection port line (PFI)

Sequential fuel injection

Common rail fuel injection

#1 Single point fuel injection or throttle body (TBI)

Fuel injection system diagram Single point first injection system carburetor replacement is a single point type. Older cars often have this type of fuel injection system because it is the simplest. A single fuel injector is located on the throttle body, mounted on the top of the intake manifold.

The throttle body receives fuel injection from the injector, which mixes with the incoming air before returning it to the engine. It consists of one or two nozzles in the throttle body of the engine, which is the throat of the air intake manifold. While injectors are not as precise as carburetors, they are more controllable, less expensive, and easier to maintain.

#2 Multi-point Fuel Injection (MPFI)

Multiple fuel injectors are used in a multipoint fuel injection system and they are located at the intake ports of each Cylinder. This system allows for better engine performance and more precise control of the fuel mixture.

This system uses multiple ports on the intake valve of each cylinder to inject fuel into the internal combustion engine. It accurately and promptly dispenses the right amount of fuel to each cylinder. MPFI systems can be classified as batch, concurrent, or sequential. Modern cars and other vehicles use it frequently.

#3 Direct Injection (DI)

Instead of the intake manifold or throttle body, Direct Injection (DI) injects fuel directly into the engine’s combustion chamber. This system allows for more precise control of the fuel mixture, which can improve engine performance, increase fuel efficiency and reduce emissions.

These are typically managed by an electronic control unit (ECU) that determines the best fuel delivery using information from various sensors. Direct fuel delivery into the combustion chamber optimizes the fuel mixture for different engine conditions, such as operating at high loads or at low speeds.

#4 Port fuel injection (PFI)

The port fuel injection system supplies fuel to the engine by placing fuel injectors inside each intake port. In a PFI system, fuel is injected into the engine’s intake ports, mixing with incoming air before entering the combustion chamber.

Fuel is supplied to the injectors under the pressure of the fuel pump. Compared to single-point injection systems, which use one fuel injector, PFI systems use multiple fuel injectors. In modern automobiles and other vehicles, gate fuel injection systems are commonly used.

#5 Sequential Fuel Injection

In a sequential fuel injection system, fuel is delivered in a specific order to the engine cylinders based on the order in which the engine burns. When the engine is idling, fuel can last for up to 150 milliseconds because they all inject at the same time or in succession.

The sequential injection has the advantage of allowing the engine to respond more quickly to sudden driver changes. This is because the valve does not need to wait for the engine to turn completely; instead, just waits for the next intake valve to open.

#6 Conventional rail fuel injection

Conventional rail fuel injection is a fuel injection system that supplies fuel to the engine’s fuel injectors through a high-pressure fuel line. The electronic control unit (ECU) manages the fuel pressure in the rails by selecting the ideal fuel pressure and timing for each injection based on information from various sensors.

Compared with other types of fuel injection systems, this system helps control the fuel mixture more precisely and improves engine performance, fuel economy, and emissions. In modern diesel engines where high-pressure fuel injection is required, it is often used.

Fuel injection system symptoms

A faulty fuel injection system typically produces a number of symptoms, such as:

Reduced fuel efficiency: The fuel injection system malfunctioned. Faulty fuel injection systems can cause the engine to consume more fuel than necessary, reducing fuel efficiency and increasing fuel consumption.

Rough idling: The engine may idling suddenly or erratically due to a faulty fuel injection system, vibrations or jerks may be felt inside the vehicle.

Engine Misfire: When the fuel injection system is not working properly, the engine may misfire or run unevenly, resulting in loss of power or stuttering during acceleration.

Starting problems: The engine may be difficult to start or may have to be started multiple times if the fuel injection system malfunctions.

Engine stall or hesitation: When accelerating or driving, the engine may stall or stall due to a faulty fuel injection system.

Check Engine Light: The check engine light may come on due to a faulty fuel injection system, which could be an engine or exhaust system problem.

Reduced Engine Power: A faulty fuel injection system can cause the engine to lose power or not operate as efficiently as it should.

Advantages of Fuel Injection System

Compared to a conventional carburetor engine, the fuel injection system has several advantages.

Here are some key advantages of the fuel injection system:

Compared to the carburetor, the fuel injection system delivers fuel more precisely and under greater pressure, allowing the engine to run more efficiently action.

The air/fuel mixture can be more precisely controlled, which can improve engine performance, smooth acceleration and reduce emissions.

This system can help reduce harmful emissions such as carbon monoxide, nitrogen oxides, and small particles.

The fuel injection system can assist with cold starting by automatically adjusting the air/fuel ratio to compensate for low temperatures.

Compared to carburetor engines, fuel injection systems are generally easier to maintain and require less maintenance.

Modern performance motorcycles can use this system.

This system helps to reduce spark plug problems and reduce engine vibration.

Disadvantages of Fuel Injection System

Although fuel injection engines have some advantages over conventional carburetor engines, there are also some potential disadvantages to be aware of.

Here are some disadvantages of the fuel injection system:

Because diagnosing and repairing the fuel injection system requires specialized knowledge and equipment, it is more complicated than in a carburetor engine.

Generally, the cost of manufacturing and installing a fuel injection system is higher than that of a carburetor engine.

Electronic components such as sensors, actuators, and control modules are required to operate the fuel injection system. There is a risk that these parts may malfunction.

To function properly, it needs clean fuel. Fuel injectors can become clogged if fuel is contaminated with debris, water, or other contaminants.

Compared to a carburetor engine, the fuel injection system can be more difficult to diagnose.

Fuel injection system diagram

Fuel injection system applications

There are various applications for fuel injection systems, some of which are listed below:

To increase efficiency Using fuel, reducing emissions, and improving engine performance, fuel injection systems are commonly used in modern automobiles.

To increase engine performance and efficiency, many modern motorcycles also use a fuel injection system to deliver fuel to the engine.

These systems are used in aircraft engines to provide precise fuel mix control and improve engine performance at high altitudes.

Marine engines, such as those found in boats and ships, use a fuel injection system to improve fuel efficiency and efficiency.

In addition, many types of industrial engines, such as those found in generators, agricultural machinery, and construction equipment, use fuel injection systems.